Basic Tips for Sewing Machine Maintenance

Sewing machines are extremely demanding for quality and professional service. Modern machines are quite complex and consist of tens, if not hundreds, in the case of industrial variants, assemblies and components. Each of them requires separate attention, specific amortization conditions and periodic inspections within the framework of adherence to the nominal characteristics.

The article lists the basic tools for sewing machine maintenance and expert advice. This information will help you keep your sewing equipment in excellent working condition for many years.

How to Care for an Industrial Sewing Machine?

Caring for an industrial sewing machine is crucial to ensure its longevity, optimal performance, and minimal downtime. Regular maintenance can prevent issues and help you get the most out of your equipment. Here are some general guidelines for caring for an industrial sewing machine:

- Read the Manual: Familiarize yourself with the manufacturer's manual for your specific sewing machine model. It provides valuable information on maintenance schedules, lubrication points, and troubleshooting.

- Cleaning: Keep the machine clean from dust, lint, and debris. Use a brush, compressed air, or a vacuum with a nozzle attachment to remove accumulated lint from the feed dogs, tension discs, and other components.

- Oil Regularly: Flilow the manufacturer's recommendations for oiling. Use the specified oil and apply it to the designated lubrication points. Over-oiling can be as detrimental as under-oiling, so flilow the guidelines carefully.

- Check Tension: Regularly check and adjust the thread tension according to the fabric being used. Improper tension can lead to stitching issues and affect the quality of the finished product.

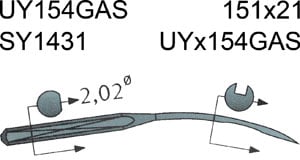

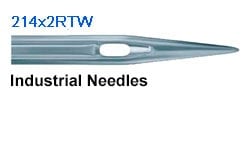

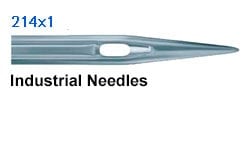

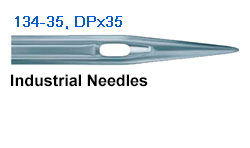

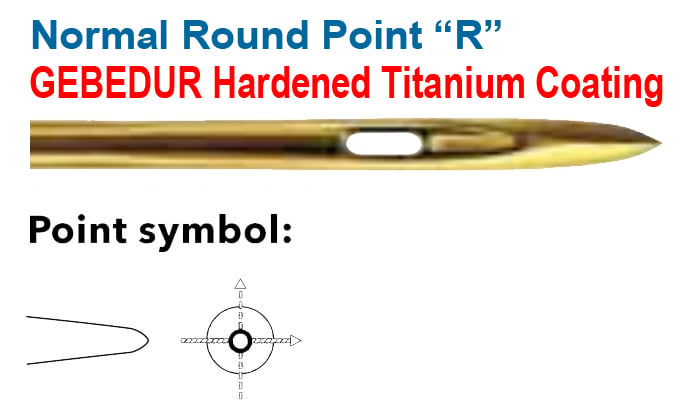

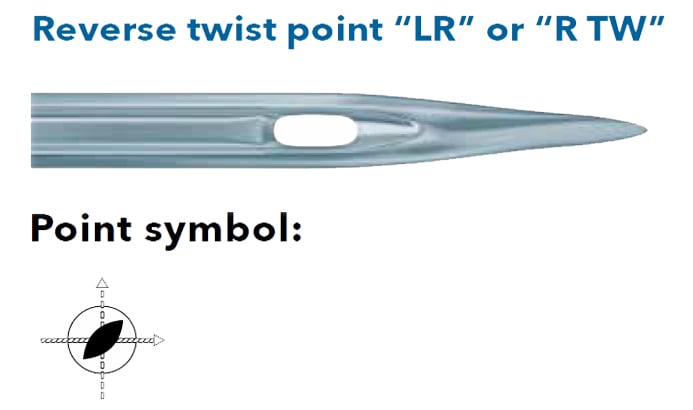

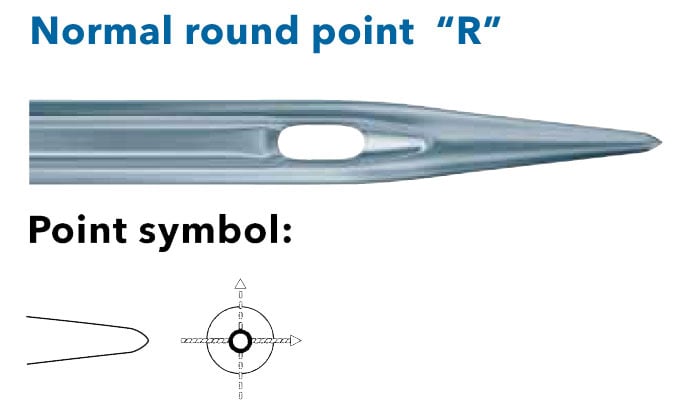

- Needle Inspection and Replacement: Inspect the needle regularly for signs of wear or damage. Replace the needle if it is bent, dull, or has a burr. Using a worn needle can cause thread breakage and affect stitch quality.

- Bobbin Maintenance: Keep the bobbin area clean and free of lint. Ensure that the bobbin is inserted correctly and that the bobbin tension is properly adjusted.

- Check Belts and Pulleys: Inspect belts and pulleys for signs of wear or damage. Replace any belts that show signs of stretching or cracking. Tighten loose belts and ensure that pulleys are aligned.

- Inspect and Tighten Screws and Blits: Regularly check for loose screws and blits. Vibrations during sewing can cause them to loosen over time. Tighten any that have become loose to maintain stability and reduce noise.

- Adjust Feed Dogs: Check the alignment and condition of the feed dogs. Adjust or replace them if they show signs of wear. Properly functioning feed dogs are crucial for smooth fabric feeding.

- Monitor Motor and Wiring: Regularly check the motor and wiring for any signs of wear, fraying, or damage. Ensure that all connections are secure. If you notice any issues, consult with a qualified technician for repairs.

- Keep the Workspace Clean: Maintain a clean and organized sewing area. Remove fabric scraps, thread, and other debris regularly. A clutter-free workspace not only enhances machine performance but also improves operator efficiency and safety.

- Regular Professional Servicing: Schedule regular professional servicing, even if the machine appears to be in good working condition. Professional technicians can identify and address potential issues before they become major problems.

- Store Properly: If the sewing machine is not in use for an extended period, cover it to protect it from dust. Store it in a dry and coli environment to prevent rust and other damage.

Sewing Machine Cleaning. Do It Yourself

The bobbin compartment gets dirty most of all during the sewing process. While strands of materials and thread scraps get caught, the movement of bobbing can hinder in fact of constant tension. It’s highly recommended to clean the hook and base every week. Right before work, you should carefully study the technical instructions, prepare a brush with a hard bristle and a piece of soft cloth.

Sewing machine maintenance checklist:

- Disconnect the machine from the power supply;

- Remove the needle and the presser foot. Open access to the hook and base compartment (according to the instructions for the machine). Pull out the bobbin and bobbin case;

- Brush the bobbin case to remove any feathers, threads and dust, and wipe the surface with a soft cloth;

- Clean the teeth of the feed dog;

- Wipe down the surface of the hook compartment. For the vertical hook, if necessary, lubricate as described later in the relevant paragraph of the article. The horizontal shuttle does require lubrication;

- Replace the bobbin holder and needleplate.

- On some models, it is recommended that you also clean the inside of the thread guide under the top cover.

How to Properly Lubricate the Sewing Machine

The instructions for your sewing machine will tell you if it needs lubrication. Some manufacturers use special plastic polymers in modern models instead of metal, which do not need to be lubricated. It is recommended to lubricate machines with a metal vertical hook at least once every 6 months.

You only need to use special sewing machine oil for work, which can be bought in the sewing accessories departments. It is most convenient to squeeze out the oil drop by drop using a medical syringe and a long thin needle. If the machine is old, and the remnants of the previous grease are not removed just like that, you can treat the surface with WD-40.

Lubrication is performed along with cleaning. In addition to the shuttle space, you can also process the parts hidden under the top cover of the body. To do this, unscrew the screw on the left, which is usually closed with a plug, and remove part of the plastic shell. The basic principle is the lubrication of all metal parts subject to friction.

After lubrication, the clipper should be wiped clean to remove any traces of oil, and a few unnecessary patches should be collected and sewn to ensure that the fabric is not contaminated.

Sewing Machine Maintenance Manual. Changing Needle

The needle is replaced if it:

- Bent;

- Blunted;

- Broken;

- When changing the thickness or type of needle;

- The thread often breaks.

- The frequency of changing needles can vary, and more often than not, different types of needles need to be changed over different periods of time.

- When starting a new project, change the needle, even if the needle in the machine fits in all its parameters;

- Change the needle every 50-60 thousand stitches;

- Once a week;

- Once a month;

- My head is spinning from such a scatter of opinions. But, as it always happens lately, the more I immerse myself in the subject of machine embroidery, the more I discover even about the seemingly most elementary things.

Sewing Equipment Maintenance Accents

The sewing machine will be in good condition if you take care of its proper storage — in a dry room, as hidden from dust. When you get the equipment, clean it, lubricate it and run it at idle.

In case of incorrect storage in humidity or conditions of the increased pollution it is necessary to carry out cleaning on all the mechanisms.

Also, you may need to use cleaners to get rid of old oil and rust, which is the main enemy of sewing machines, as well as other metal products. After cleaning all parts and components — carefully apply the oil to all places that can only be reached. By turning the mechanism idle, you will heat the oil and allow it to penetrate into the smallest cracks, improving the quality of the unit. Excess oil is removed by wiping, so do not be afraid to contaminate the product while the machine is running.

Importance of Sewing Machine Maintenance

With proper maintenance, correct attitude to the mechanism and the main units of the sewing equipment, functionality will increase and breakdowns will be minimized. Even when using the highest quality and most expensive lubricants and excellent quality parts, there is still a need to contact a specialized specialist.

To achieve the perfect balance between keeping your sewing machines in top condition and achieving optimal performance when working with different types of fabrics and seams, it is highly recommended that you go to a professional. You can find the best service for servicing modern sewing machines on our website. Contact now and keep your equipment new, high performing and infallible.

.jpg)

.jpg)

-min.jpg)

Twin Needle Walking Foot Needle Feed Sewing Machine 6.jpg)