How to Wind a Bobbin on Your Sewing Machine

Professional sewing equipment is a complex mechanism, requiring professional service. One of the most important aspects of correct operation is the adequate winding of the working bobbin.

High-class specialists know that this seemingly insignificant detail is one of the most important components of the equipment. All parts and components of the sewing machine must process in a balanced and collaborative manner. Even taking into account the bobbin case is only a small part of the sewing machine mechanism doesn’t affect the fact that its correct winding is the basis for quality, professional work and the creation of high quality products . To understand, how to wind a bobbin — follow the article.

How to Wind a Bobbin on a Sewing Machine

Professional sewers should be aware of all aspects of the operation of each individual component of industrial and domestic sewing machines. The functionality of separate components affects the quality of the product as a whole, so for a professional result, the careful maintenance of the entire mechanism of the sew equipment is required. Each, the smallest parameter, of the sewing process, depends on the accuracy of setting the individual components of the equipment. Also, be sure to take into account the fact that depending on the model used, the process and result of the work may differ significantly, as well as the functionality of the most important components.

One of the most important parts of modern sewing equipment is the bobbin. Such a minor but important detail, it affects the entire sewing process from the beginning to the end of a seam on a manufactured textile. It is in the bobbin case the main working thread is pulled out, allowing to process smoother and better seams.

One of the key factors is the bobbin material. In the modern market for professional and home sewing equipment, there are two main types of bobbin cases — made out of high quality plastic and metal. The overwhelming majority of experts recommend using metal bobbin cases and bobbins — they are also the components of most professional industrial equipment.

On the other hand, the plastic bobbins slide much more easily inside the bobbin case, creating optimal thread tension. Note that if the bobbin breaks, it will need to be replaced, and plastic counterparts cost less. Also, focus on the fact that not all bobbin cases are interchangeable — in case of breakage, it is recommended to consult with a profile specialist, for example, a consultant at a sewing accessories store.

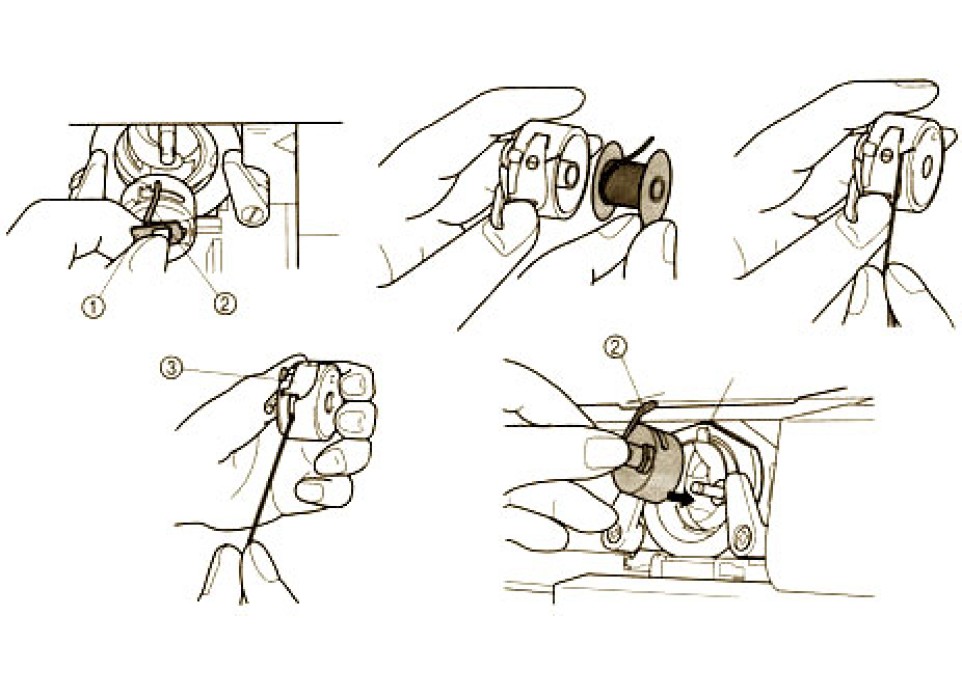

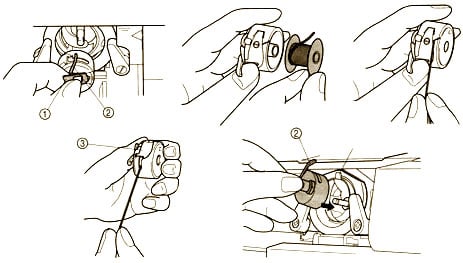

Winding a Bobbin Guide

During the process of adjusting the operating mode of modern sewing equipment, sewer will come across two main types of bobbin cases: front (this one with an inserted hollow body), and top (with a specific insertion device).

For successful setting up the machine, follow the next, simple steps:

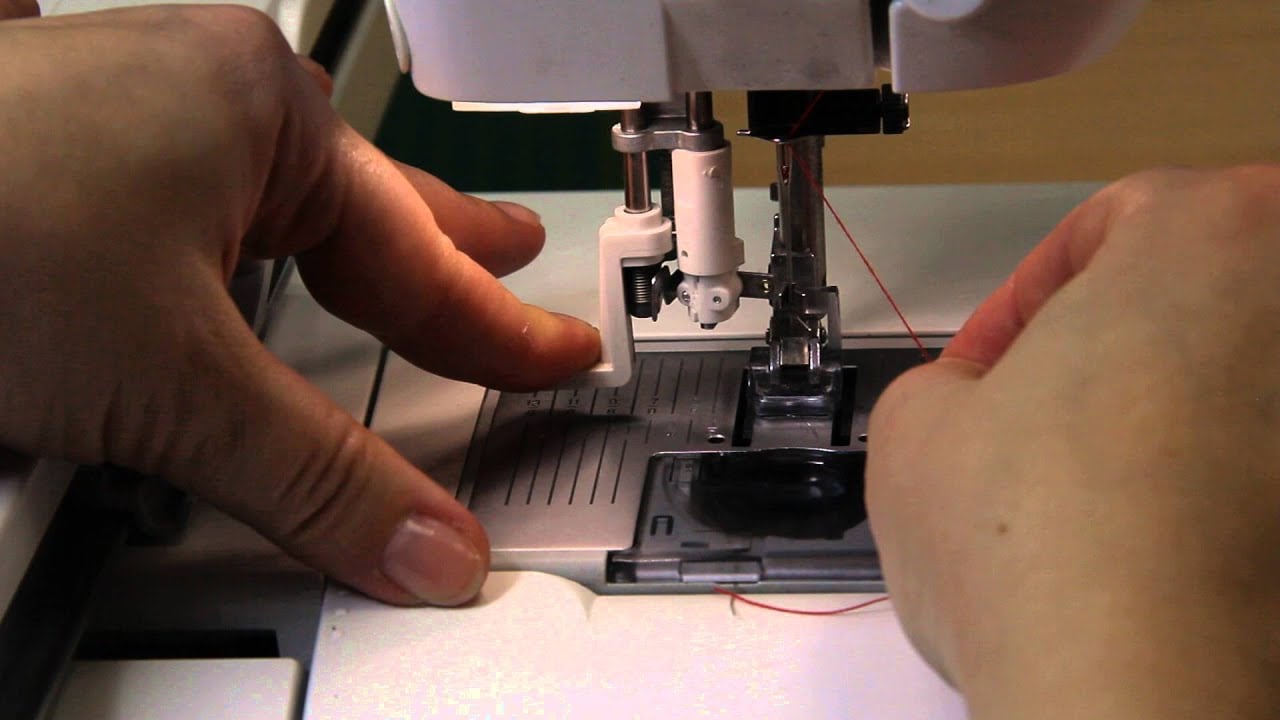

- Remove the bobbin case from the base of the machine. At the same time, during removal, make sure that the working needle is in the fixed «up» position so as not to damage the main mechanism. Then, pre-set the sewing machine to medium speed — this is the best solution for later checking that the bobbin case is wound correctly. The bobbin must be completely empty — remove the old thread, select a new color or thread type. In any case, if you rewind the bobbin, then the thread must be replaced. Please note that different types of thread may require different types of bobbins, so check this aspect with the basic parameters and production specifications;

- Determine the thread winding path that should end directly on the machine's work spindle. Determine in advance all the key aspects of the thread following the equipment and mark them for yourself — at least on the diagram in the instructions (commonly provided with pictures) for the equipment.

- Lock the wheel of the sewing machine so that it doesn’t turn on automatically while rewinding the bobbin. In this case, the work needle is blocked, which allows the thread to be drawn directly to it to fix it in the required position for sewing. To secure the needle in the correct position, you will need to adjust it using a special handle — in most cases, it is located inside the working handwheel;

- Right after securing the working needle, the operator of the equipment should thread the main working needle. The bobbin must be facing up strictly. The working thread is wound around the thread guide — there is a small hole at the very top of the spool. While winding a bobbin, place the main working thread around the bobbin by hand, then this will occur automatically;

- Lock the mechanism. Then, the operator should press the bobbin winder and check if the bobbin is on the right side. After that, the mechanism will be prepared to start;

- Start automatic winding. Highly recommended to start deliberately to make sure that the thread is wound in the correct direction and the thread is not twisted — this can backfire;

- The starting thread should be carefully cut so that it doesn’t snag on the protruding parts of the sewing mechanism. Please, note that most modern sewing machines stop operating automatically when the bobbin is full.

- Next, you must open the bobbin

winder, engage the wheel, and cut the working thread. Immediately after this, the winding process will automatically end — the operator of the sewing equipment can proceed to further work. - So, how do I wind the bobbin? Now you’ve got answers.

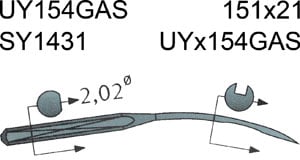

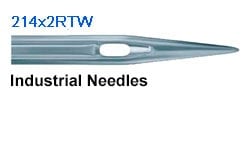

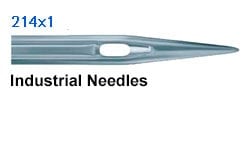

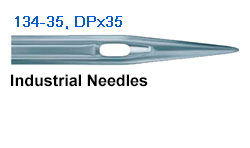

If you need bobbin, You can buy it on Konsew LTD. We offer all the top brands with delivery. The most popular:

.jpg)

.jpg)

-min.jpg)

Twin Needle Walking Foot Needle Feed Sewing Machine 6.jpg)