Buttonhole sewing machine

There are no products to list in this category.

Industrial Buttonhole Sewing Machine Choosing Aspects

A sufficiently wide list of specialized equipment is required to provide industrial sewing enterprises with the necessary tools. Particular attention is paid to sewing fashion clothing items, which, in turn, requires an emphasis on the high-quality flashing of buttonholes. Buttonholes are probably the most complex elements of any garment that every manufacturer should pay attention to.

Choosing an industrial buttonhole machine for loops is an extremely important task in case you decide to organize the mass production of clothes.

The Main Choosing Tips for Button Hole Machine

While choosing equipment for loops and buttonholes, you need to comprehend the way they differ. All models of sewing equipment provide various opportunities for the production of different types of accessories and the processing of diverse thread types.

➰ How to choose Buttonhole Sewing Machine❓

Specialized models have the greatest number of unique characteristics that distinguish this type of equipment in a separate category:

- The number of built-in stitch types. Buttonholes require special attention and the use of unique stitches to achieve the desired aesthetic and practical effect. Modern sewing machines guarantee a huge number of supported types of seams — from several dozen to 60+ types, which guarantees high-quality finishing of almost all elements of clothing — from coarser buttonholes, say, in denim, to filigree silk and firmware cotton fabric requiring high-quality stitching loops;

- Numerous types of buttonholes. The most advanced models provide the ability to process dozens of different buttonholes. For a manufacturing enterprise, more multifunctional models are more suitable, capable of directly changing the style of processing button openings on the go, allowing you to make a wide variety of elements of clothing and fabric;

- Adjustable Stitching Speed. Most models for buttonholes are characterized by lower sewing speed, but they sew holes for buttons better and better. To sew on an industrial scale, be sure to choose sewing machines with the highest processing speed, as this will provide you with optimal productivity when working with all kinds of loops, buttons, and decorative holes;

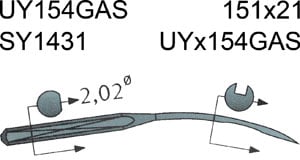

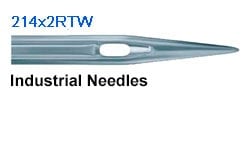

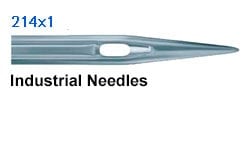

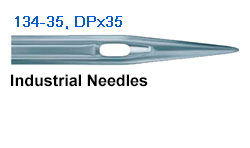

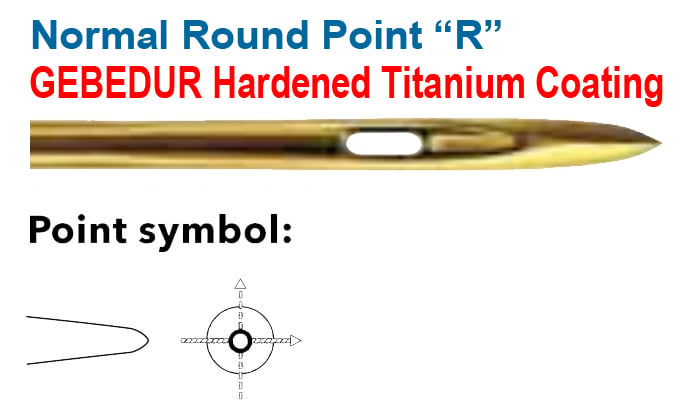

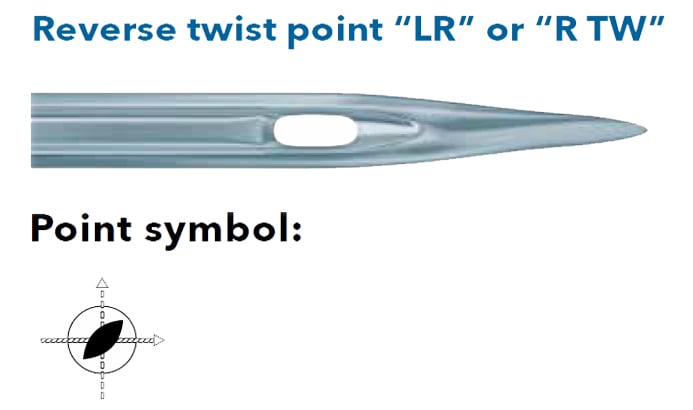

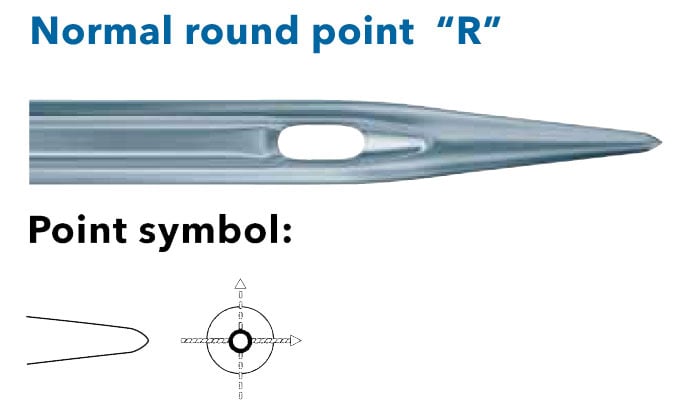

- Automatic Needle Threading. Thanks to this convenient option, you may easily and quickly change the needle in case of breakage. A very necessary function for button hole machine on an industrial scale, since when processing especially hard kinds of tissue material, the needles can break often;

- Multiple Presser Foot. Since the process of flashing holes for buttons and loops is extra demanding on the accuracy of each seam and pattern, due to the shorter distance between them, industrial buttonhole models are more demanding on the flexibility of pressing the material and the possibilities of its rotation. While providing equipment for a business, Be sure to pay attention to the number of presser feet — there should be at least 5-10 of them;

- Free Arm. An excellent option for sewing machines due to the extreme convenience when sewing cuffs, sleeves, and other items of clothing that require firmware from several sides, which makes it necessary to rotate them around the presser feet.

Online Store Assortment of Buttonhole Sewing Machine

⚡ ⚡ ⚡ What buttonhole sewing machine can we offer❓

At the moment, our store presents the best types of industrial sewing machines, in terms of a manual expert assessment by qualified specialists:

- Jack JK-9820-01 Electronic Eyelet Keyhole Buttonhole Sewing Machine. An excellent choice for a complete set of industrial enterprises due to the electronic control system. The equipment uses an automated mechanism, fully controlled by a step servo drive motor, providing operator comfort with constant sewing. High sewing speed (2500 stitches/minute) provides an excellent level of productivity and excellent quality of each seam;

- Jack JK-T1790B Electronic Lockstitch Buttonhole Machine. The highest switching speed and high-quality processing of many types of buttonholes, provided by a heavy-duty platform using innovative technologies — in particular, an electronic device for controlling the tension of a Beautiful Stitch technology. Additionally, it’s equipped with an excellent cooling system and a multi-cut system, which ensures that there is no need to change the knife during fabric cutting;

- Brother RH-9820-01 Electronic Eyelet Keyhole Buttonhole Sewing Machine. Highly professional industrial equipment, equipped with everything necessary for sewing on several stored in the electronic pattern management system. The needle feed and rotation mechanism is automatically adjusted to provide increased reliability for each separate stitch. The presence of a full-format control panel guarantees the widest possibilities for fine-tuning all geometric sewing parameters.

Reviews about Buttonhole sewing machine

.jpg)

.jpg)

-min.jpg)

Twin Needle Walking Foot Needle Feed Sewing Machine 6.jpg)