JUKI MF7923U 5.6MM Cylinder arm coverseam pneumatic Industrial sewing machine

JUKI MF7923U11B56/UT59 3N 5.6MM Pneumatic Industrial sewing machine

The machine can be used for the hemming process of the sleeves and bottoms of T-shirts and for the covering process for sportswear and knitwear. The front cover is trimmed to allow operators to bring their hands closer near the needle entry area, thereby increasing work efficiency in the covering process, etc. It uses air to power its main functions, so you will need to have a compressor alongside this machine.

The Juki MF-7900 Series is a newly developed

coverstitch machine provided with lots of

mechanisms for improving the seam quality.

It is provided with many different sewing-related mechanisms which contribute to

improved seam quality, such as the new feed mechanism, and differential-feed

micro-adjustment mechanism. In addition, the machine is provided as standard with

a looper thread twining prevention mechanism for improved maintenance.

Thanks to the new feed mechanism,

many different types of sewing are achieved.

The feed locus can be adjusted externally. The

feed locus is now adjustable in terms of the

vertical direction and horizontal direction, thereby

improving responsiveness to sewing materials.

Micro-lifter mechanism

Elastic material or delicate material can be

sewn with the presser foot kept slightly raised.

This effectively helps reduce the degree of

slippage, warpage and damage of the material.

Differential-feed micro-adjustment mechanism

It is possible to finely adjust

the differential feed amount

to a best-suited value for the

material to be used.

The differential feed ratio is

constant even if the stitch

length is changed.

The looper thread twining prevention mechanism has been

improved and is provided as standard for the sewing machine.

In the case of looper thread breakage,

the looper thread twining prevention

mechanism is activated to trim the

looper thread before the thread twines

on the looper thread cam. In this way,

the looper thread twining prevention

mechanism prevents the looper

thread from twining on the looper thread cam. In addition, the looper

thread cam, which has been incorporated in the sewing machine, has

been changed so that it is mounted outside of the sewing machine. The

externally-mounted looper thread cam promises improved maintainability.

All of the sewing machines with

a thread trimmer are provided

with a direct-drive motor.

The direct-drive motor system has been

adopted by all of the sewing machines with

a thread trimmer. As a result, the sewing

machine starts up swiftly and promises

increased stop accuracy, thereby

demonstrating improved responsiveness.

In addition, the machine is no longer

provided with a V-belt. This means that the

adoption of the direct-drive motor is also

effective in the elimination of belt shavings. Power is directly transmitted

from the motor to the sewing machine, thereby contributing to reduced

power consumption. (This sewing machine reduces power consumption

by 27% as compared with the conventional models.)

This machine comes with 12 months guarantee.

| Features | |

| Application | From light to medium-weight materials |

| Bed Type | Cylinder-bed |

| Brand | Juki |

| Feed Type | Differential-feed |

| Lubrication | Automatic-lubricating |

| Machine Level | Auto-Functions |

| Machine Type | Coverstitch |

| Manufacturer’s guarantee | This machine is offered with a 12 month back to base Guarantee |

| Max lift of the presser foot | 5mm |

| Max stitch length | 4mm |

| Needle gauge (mm) | 5.6 mm - the standard in the industry |

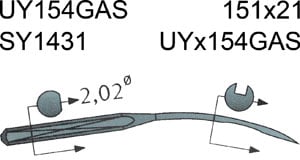

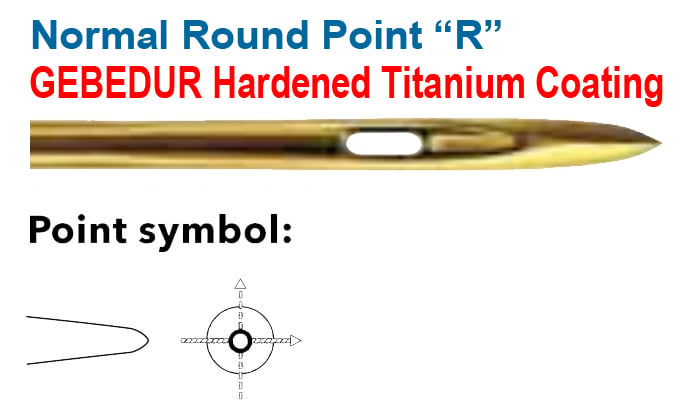

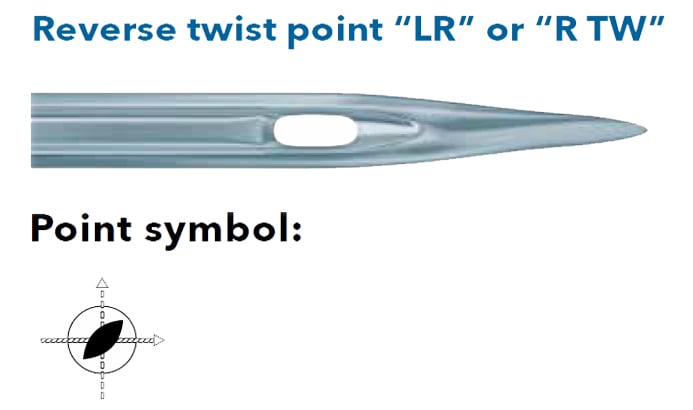

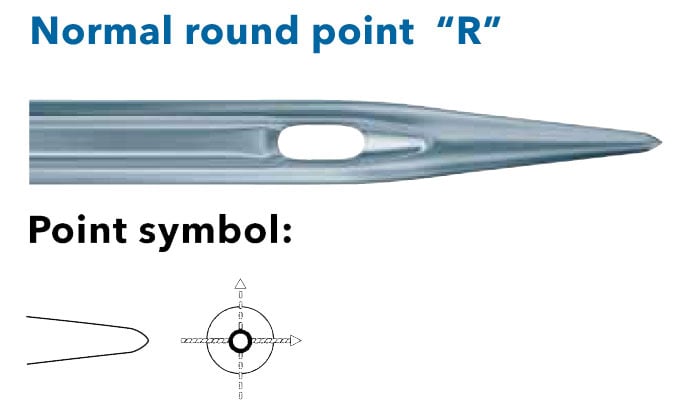

| Needle System | Uy128GAS size 11 – 16. |

| Number of threads | 5 |

| Power requirement | Single-phase 200V~240V 13 amp (can be used at home) |

| Stitch type | 2-needle/3-needle top and bottom covering stitch |

| Table top dimensions | L105cm x W60cm Height Adjustable from 70cm to 86cm |

| Type | Top & Bottom Coverstitch or Two Rows on Top, Coverstitch on Bottom |

| Max Sewing Speed (sti/min) | 5000 Stitches Per Minute |

| Number of needles | 3 |

Name

Review

.jpg)

.jpg)

-min.jpg)

Twin Needle Walking Foot Needle Feed Sewing Machine 6.jpg)

Lockstitch Industrial Sewing Machine With British Table Top..-min-195x195.jpg)