General problems of sewing machines and their solutions

Sewing machines can encounter various problems during use, but many of these issues have straightforward solutions. Here are some common problems with sewing machines and their potential solutions:

Machine not sewing/running: If your sewing machine isn't sewing or running at all, check to ensure it's properly plugged in and turned on. Also, inspect the power cord and foot pedal for any damage. If everything seems fine, there might be an issue with the internal wiring or motor, and you may need to consult a professional repair technician.

Thread tension issues: Incorrect thread tension can result in loose or tight stitches. Check that the machine is threaded correctly and that the tension settings are adjusted appropriately for the fabric you're sewing. If the tension is too tight, try lowering it, and if it's too loose, try increasing it gradually until you achieve balanced stitches.

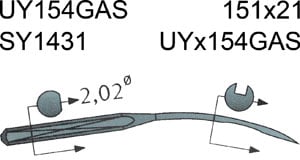

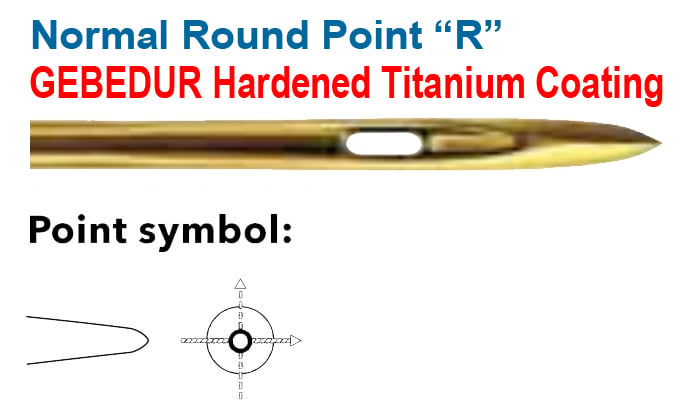

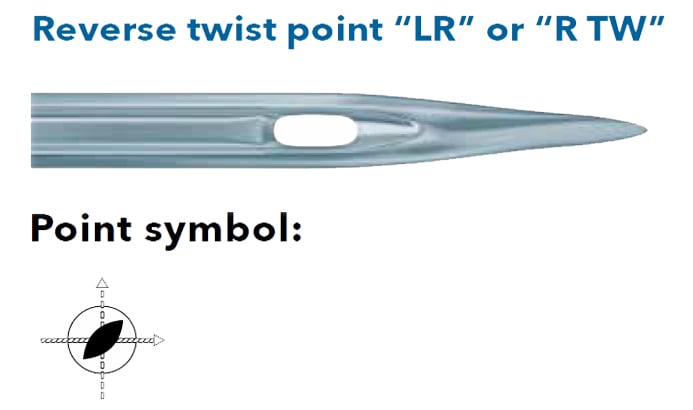

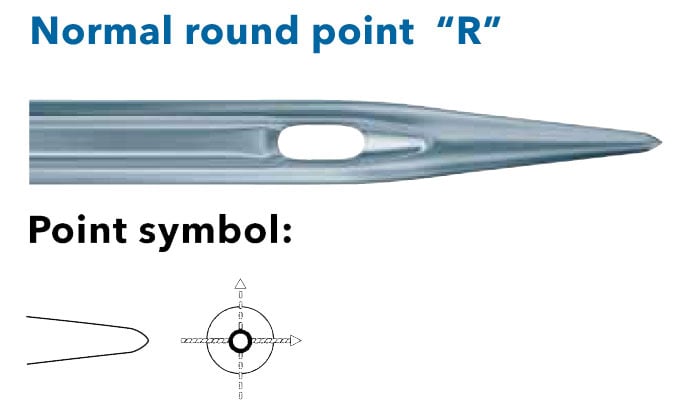

Skipped stitches: Skipped stitches can occur due to various reasons, including a dull or bent needle, incorrect needle size for the fabric, or improper threading. Try changing the needle, ensuring it's inserted correctly and securely, and using the appropriate needle size and type for your fabric. Additionally, make sure the machine is threaded correctly and that the needle and thread are compatible.

Breaking needles: Broken needles can be caused by several factors, such as using the wrong needle size or type, sewing over pins, or sewing through thick layers of fabric. Always use the appropriate needle for your fabric, remove pins before sewing over them, and consider using a walking foot or a heavy-duty needle for sewing thick fabrics or multiple layers.

Machine jamming or fabric bunching: If your machine is jamming or causing the fabric to bunch up under the needle, check for tangled thread in the bobbin area or around the feed dogs. Clean the bobbin area and feed dogs regularly to remove lint, dust, or stray threads that can interfere with the sewing process. Additionally, ensure the machine is threaded correctly and that the bobbin is wound evenly and inserted properly.

Uneven stitches or puckering: Uneven stitches or puckering can result from incorrect tension, improper threading, or using the wrong needle or thread for the fabric. Adjust the tension settings, rethread the machine, and double-check the needle and thread compatibility. Experiment with different needle types and thread weights to find the best combination for your fabric.

Noisy operation: Excessive noise during sewing can indicate a problem with the machine's internal components, such as worn-out gears or lack of lubrication. Consult the machine's manual for instructions on oiling and maintaining your sewing machine, and consider taking it to a professional technician for servicing if the noise persists.

By troubleshooting these common problems and following proper maintenance practices, you can keep your sewing machine in good working condition and enjoy seamless sewing experiences.

.jpg)

.jpg)

-min.jpg)

Twin Needle Walking Foot Needle Feed Sewing Machine 6.jpg)