Sewing machine needles

- 16x231, DBx1 Industrial needles

- 134R, DPx5 Industrial needles

- 135x17, DPx17 Industrial needles

- B27, DCx27 Industrial overlock needles

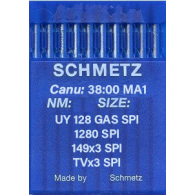

- UY128GAS Industrial coverstitch machine needles

- 16x95 Groz Beckert Needles

- LWx6T Blindstitch Needles

- 130/705 H Schmetz domestic needles

- 251 LG Groz Beckert Needles

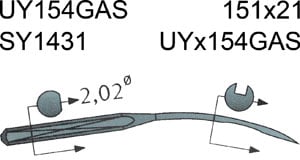

- UY154GAS Curved overlock needles

- 149X5 TVX5 Industrial needles

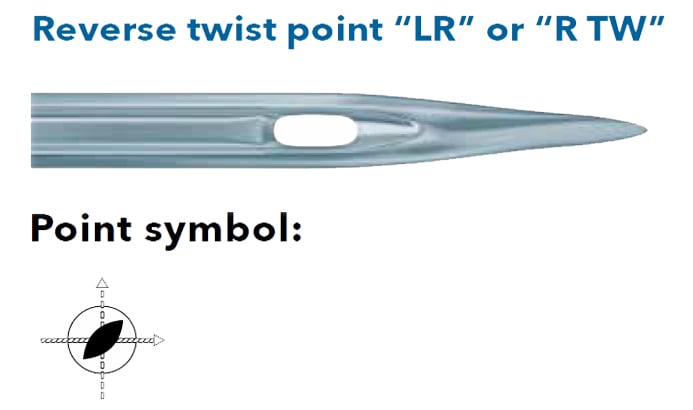

- 214x2RTW Industrial needles

- 214x1 Industrial needles

- DBxK5 Schmetz needles

- DOx558 Buttonhole Machines Needles

- 29x4NTW Schmetz Leather Needles

- 88x1 Schmetz Needles

- 7x3 Groz Beckert Needles

- DPx35 134-35 Industrial needles

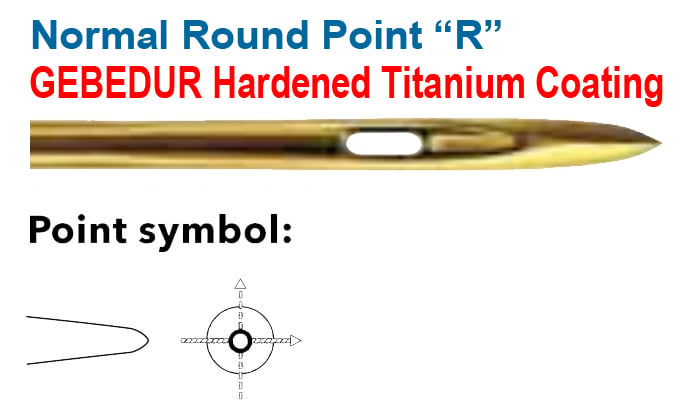

- Titanium coated

- Ballpoint needles

- Leather point needles

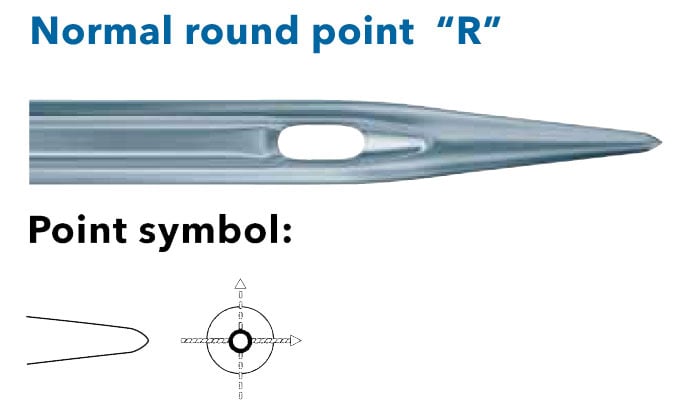

- Regular point needles

- Schmetz industrial needles

- Groz Beckert industrial needles

- 16x231, DBx1 Industrial needles

- 134R, DPx5 Industrial needles

- 135x17, DPx17 Industrial needles

- B27, DCx27 Industrial overlock needles

- UY128GAS Industrial coverstitch machine needles

- 16x95 Groz Beckert Needles

- LWx6T Blindstitch Needles

- 130/705 H Schmetz domestic needles

- 251 LG Groz Beckert Needles

- UY154GAS Curved overlock needles

- 149X5 TVX5 Industrial needles

- 214x2RTW Industrial needles

- 214x1 Industrial needles

- DBxK5 Schmetz needles

- DOx558 Buttonhole Machines Needles

- 29x4NTW Schmetz Leather Needles

- 88x1 Schmetz Needles

- 7x3 Groz Beckert Needles

- DPx35 134-35 Industrial needles

- Titanium coated

- Ballpoint needles

- Leather point needles

- Regular point needles

- Schmetz industrial needles

- Groz Beckert industrial needles

Currently, there are many sewing machines types, which differ in a variety of parameters. Thus, wrong needle choice is fraught not with only its breakage, but also inadequate stitching quality, fabric damage. In this article, we'll look at the main criteria.

.jpg)

⭐Sewing machine needles classification

For fabrics of various density, the diameter of the different needles is used.

Accordingly, sewing needles for the sewing machine are divided into three main groups:

- Light includes 60 (8), 70 (10), 80 (12) and is intended for cotton, silk and synthetic fabrics like crepe de Chine, batiste, gauze, tricot.

- Medium contains 80 (12), 90 (14) and 100 (16) are used for standard thickness materials - flax, cotton, twill, percale, knitwear.

- Heavy comprises numbers: 100 (16), 110 (18), 120 (19) are for tick, tweed, gabardine, drapery fabrics, reps processing.

The second number in the brackets also indicates diameter, but only in hundredths of an inch. For each number of needle, there is intended certain thickness thread, which is also labelled.

There is a close connection between the needle points and textiles: it penetrates between the fibres, connecting it:

- Universal Needles (Fabric: Cotton, linen, polyester blends, lightweight wovens)

Description: Universal needles are a versatile choice for general sewing. They have a slight ballpoint tip, making them suitable for various fabrics. However, they may not be the best choice for heavy fabrics or specialty materials. - Ballpoint Needles (Fabric: Knits, jersey, interlock, spandex)

Description: Ballpoint needles have a rounded tip that slips between fabric threads rather than piercing them. This makes them ideal for knit fabrics without causing snags or damage. - Sharp Needles (Microtex, Quilting) (Fabric: Silk, tulle, organza, lightweight cotton)

Description: Sharp needles have a slender body and a fine, pointed tip. They are designed for delicate and lightweight fabrics to prevent snags or runs. - Jeans/Denim Needles (Fabric: Denim, canvas, heavy twill)

Description: Jeans needles have a strong, thick shaft and a very sharp point. They are designed for sewing through multiple layers of heavy fabrics like denim without breaking. - Quilting Needles (Fabric: Quilting cotton, lightweight wovens)

Description: Quilting needles have a tapered point that easily pierces multiple layers of fabric. They are suitable for quilting and piecing projects. - Embroidery Needles (Fabric: Specialty fabrics, embroidery stabilizers)

Description: Embroidery needles have a larger eye to accommodate embroidery threads. They work well with specialty fabrics and stabilizers used in embroidery projects. - Stretch Needles (Fabric: Lycra, spandex, elastic fabrics)

Description: Stretch needles are designed for fabrics that stretch. They have a deeper scarf (the indentation above the needle eye) to prevent skipped stitches on stretchy materials. - Topstitch Needles (Fabric: Heavy fabrics, decorative topstitching)

Description: Topstitch needles have a larger eye, allowing for the use of heavier threads. They are suitable for decorative topstitching on heavy fabrics. - Leather Needles (Fabric: Leather, faux leather)

Description: Leather needles have a chisel tip and are designed for sewing through leather and other heavy non-woven materials. They cut through the material rather than piercing it. - Twin Needles (Fabric: Knits, hems, decorative stitching)

Description: Twin needles have two needles on a single shaft and are used for creating parallel rows of stitching. They are commonly used for hems on knit fabrics.

In order for the machine to do perfect stitches, you should correctly choose type, point, and thickness of the needle.

The shapes of the sewing needle shanks

The shank is an important part of the needle. It has round and flat sides.

But, the shank can be totally round: it’s designed for use in professional machines.

For domestic machines applying the only needles with a plane shank.

The discrepancy in the needle, thread, shank parameters leads to a quality seam decrease and other problems.

⭐What do size numbers of industrial sewing machine needles mean?

Each needle has a specific marking, that consists of numbers and letters. The first determines a thickness, expressed in hundredths of a millimetre, the second - sharpening.

It should be selected in accordance with the material type.

- Type H, universal. The size: 60-110; rounded tip. Apply for simple fabrics.

- Type H-J. The size: 100-110; sharp edge. Using while sewing thick fabrics such as denim, leather or tarpaulin.

- Type H-M. The smallest sizes; thin, sharp. It’s used while stitching products from a micro-fibrous and thin material (taffeta, silk, etc.).

Each needle has its own specific label, which is an excellent source of the necessary information. Thanks to it, the user can independently find a suitable one!

⭐What brands are the best needles manufacturers for industrial and domestic machines?

German industrial sewing machine needles of Groz-Beckert and SCHMETZ are the most lasting and durable. High quality and long service life are connected with titanium nitride coating, protecting against breakages. These companies are constantly working on updating the sewing machine needles range and put them up for sale around the world and also in the UK.

⭐What is the assortment of sewing needles for sewing machine in our store?

In our online store, there are presented two good sewing needles manufacturers - Groz-Beckert and SCHMETZ. These two companies produce high-quality needles from a materials variety, as well as special applications.

Pay attention, that all products in "Konsew" have a good commercial price!

Buy your ideal set of sewing machine needles!

.jpg)

.jpg)

-min.jpg)

Twin Needle Walking Foot Needle Feed Sewing Machine 6.jpg)