Genuine industrial machines are built to last for many years with proper maintenance.

Absolutely, one of the hallmarks of genuine industrial sewing machines is their longevity when properly maintained. Here's why these machines are built to last:

High-Quality Materials: Industrial machines are constructed using durable materials such as cast iron, steel, and aluminum, ensuring longevity and resistance to wear and tear.

Precision Engineering: Industrial sewing machines undergo meticulous design and engineering processes to ensure all components work together seamlessly, minimizing the risk of breakdowns over time.

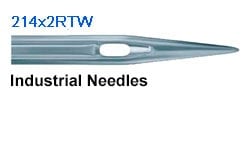

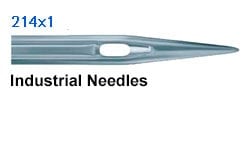

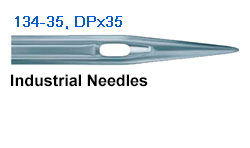

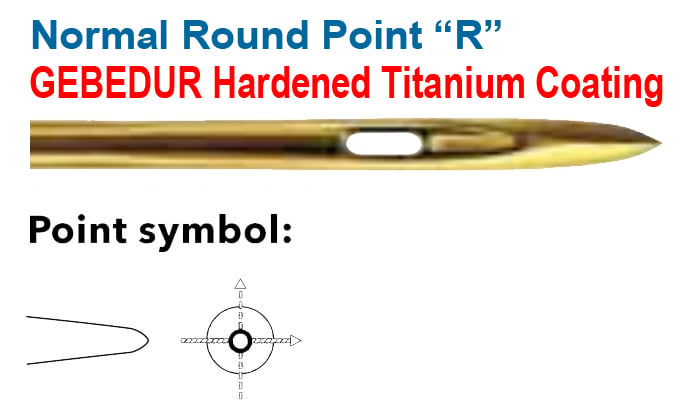

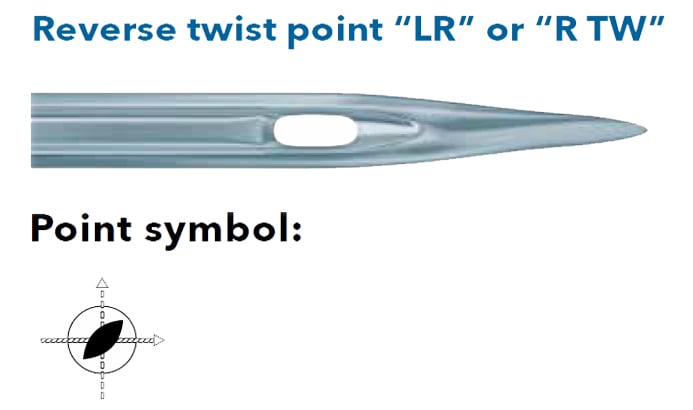

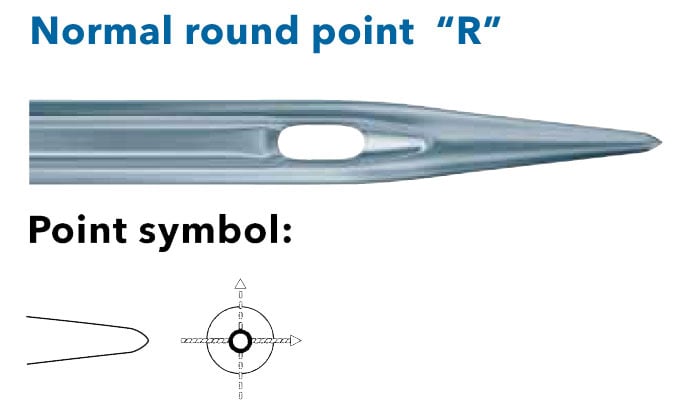

Heavy-Duty Components: Critical parts of industrial machines, including the motor, gears, and needles, are designed to withstand the demands of continuous use in commercial settings.

Regular Maintenance: With proper care and maintenance, including routine cleaning, lubrication, and adjustments, industrial sewing machines can continue to operate efficiently for many years.

Accessibility of Parts: Manufacturers of genuine industrial machines often provide readily available replacement parts, ensuring that repairs can be made promptly to extend the machine's lifespan.

Built-In Durability Features: Industrial machines are equipped with features such as overload protection, automatic thread cutters, and self-lubricating systems, further enhancing their durability and reliability.

Reputation of Manufacturers: Reputable manufacturers of industrial sewing machines stand behind their products, offering warranties and support services to ensure customer satisfaction and machine longevity.

Overall, genuine industrial sewing machines are designed and built with longevity in mind, making them a sound investment for businesses looking for reliable and durable equipment to support their operations over many years

.jpg)

.jpg)

-min.jpg)

Twin Needle Walking Foot Needle Feed Sewing Machine 6.jpg)