How Often Do We Have to Change Needles in an Industrial Sewing Machine

The frequency of changing needles in an industrial sewing machine depends on various factors, including the type of fabric being sewn, the volume of work, and the type of needle being used. Here are some general guidelines:

Type of Fabric:

Different fabrics can have varying levels of abrasiveness. Sewing through heavy or abrasive fabrics, such as denim or leather, can dull needles more quickly than sewing through lighter materials. If you're working with tough fabrics, you may need to change needles more often.

Volume of Work:

High-volume production or extended sewing sessions can contribute to faster needle wear. In industrial settings where the machine is in constant use, needles may need to be changed more frequently compared to lower-volume settings.

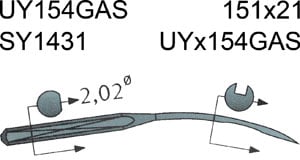

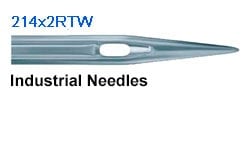

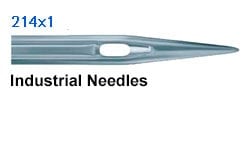

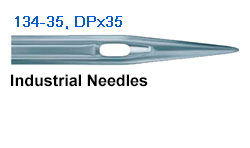

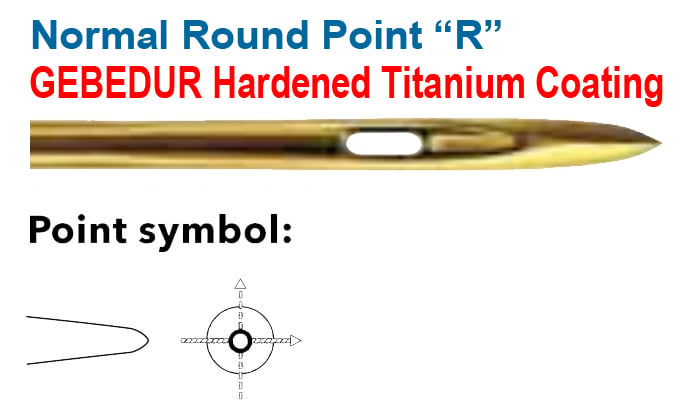

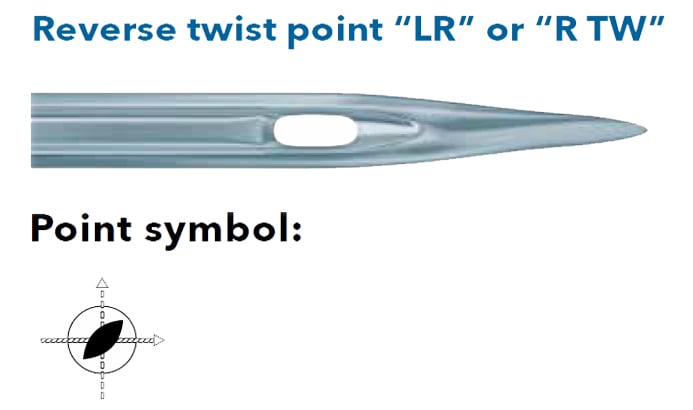

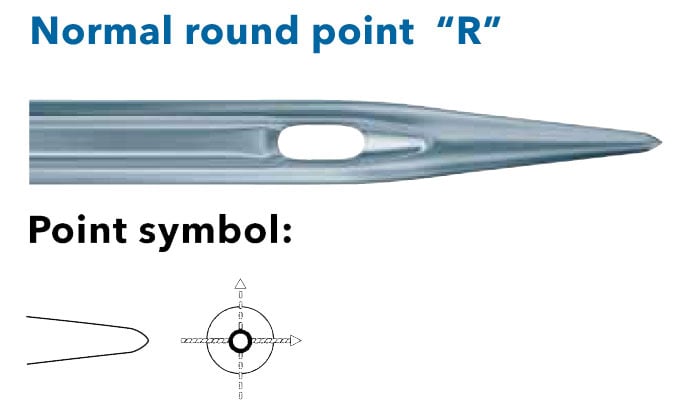

Needle Type:

The type of needle you use also affects how often it needs to be changed. For example, ballpoint needles are designed for knits and stretch fabrics and may need to be changed more often than universal needles used on woven fabrics.

Task Complexity:

If you are performing intricate or detailed stitching, the needle may experience more stress and wear. Changing the needle regularly is important to maintain the quality of stitching.

Needle Size:

The size of the needle, indicated by the needle number, also plays a role. Smaller needle sizes may wear out more quickly than larger sizes, especially if they are used on heavy fabrics.

As a general guideline, it's recommended to change needles after every 8–16 hours of sewing time, even if they don't appear visibly damaged. If you notice any of the following signs, it's time to change the needle:

Dull or Blunt Tip: A needle with a dull or blunt tip may not pierce through fabric cleanly, leading to skipped stitches or uneven stitching.

Bent Needle: If a needle is bent, it can cause stitching issues and potentially damage the fabric.

Visible Damage: Inspect the needle for any visible signs of damage, such as burrs, nicks, or bends.

Thread Breakage: Frequent thread breakage can be an indication that the needle is not in optimal condition.

Puckering or Uneven Stitches: If you notice puckering or uneven stitches, it could be a sign that the needle is not performing effectively.

Remember that regular needle changes contribute to better stitch quality, prevent damage to the fabric, and reduce the likelihood of machine issues. Additionally, always use the appropriate needle type and size for the fabric you are sewing to achieve the best results.

.jpg)

.jpg)

-min.jpg)

Twin Needle Walking Foot Needle Feed Sewing Machine 6.jpg)