Pegasus M952-52-2x4(/D222) 4 thread industrial overlock

Pegasus M952-52-2x4(/D222) 4 thread industrial overlock

The Pegasus M952 is an industrial overlock sewing machine commonly used in the textile and garment industry. It is designed for high-speed production and is capable of performing three-thread overlock stitches.

Here are some key features and specifications of the Pegasus M952

Stitch Formation: The machine is capable of creating four-thread overlock stitches. This stitch type is commonly used to finish raw fabric edges, prevent fraying, and provide a clean and professional finish.

Speed: The Pegasus M952 is designed for high-speed operation, allowing for efficient and rapid production. The exact speed may vary depending on the specific model and settings.

Differential Feed: This machine typically includes a differential feed mechanism. The differential feed allows you to control the feeding of the fabric, which is especially useful when working with stretchy or lightweight materials. It helps prevent puckering or stretching of the fabric during sewing.

Thread Tension Control: The machine is equipped with individual thread tension controls for each thread. This allows you to adjust the tension of each thread according to the specific fabric and stitch requirements, ensuring balanced and even stitching.

Cutting Mechanism: An integral part of an overlock machine is its cutting mechanism. The Pegasus M952 typically includes a built-in fabric-cutting system that trims the fabric edge while simultaneously sewing the overlock stitch.

Stitch Length Adjustment: The machine allows you to adjust the length of the overlock stitches according to your requirements. This feature enables you to customize the stitch appearance and adapt to various fabric types or sewing techniques.

Industrial-Grade Construction: The Pegasus M952 is built for heavy-duty use in industrial settings. It features sturdy construction, durable components, and reliable performance to withstand the demands of continuous production.

This M900 Series machine with Pegasus Built-in Direct drive motor offers all the features you would expect, Auto oiling push button stitch length adjustment, and easy-adjust differential feed so you can get those seams looking perfectly flat. Easy-to-follow threading, super smooth motor sewing at 7000 stitches per minute. This machine is simple to use, high-quality finish, and incredibly reliable

Thanks to our excellent oil-blocking mechanisms, including a totally enclosed needle bar chamber, with a force-drain function, and other similar features, the Pegasus M900 series protects your important sewn products from oil stains.

The upper looper mechanism includes special functions, so dirt prevention measures have been strengthened further. This machine-friendly feature prevents dirt and dust from getting into the inside of the machine, contributing to an increase in production.

Achieves a maximum machine speed of 7,000 sti/min resulting in production increases

Introduction of the rustproof needle plate

The Needle plate is surface-treated as a rust-prevention measure. Thanks to this feature, the needle is not damaged by fabrics processed with chemical agents and/or dyes.

Comes with a 12-month guarantee.

| Features | |

| Application | From light to medium-weight materials |

| Bed Type | Flat-bed |

| Brand | Pegasus |

| Differential feed ratio | Gathering 1:2 (Max. 1:4), Stretching 1:0.7 (Max. 1:0.6) |

| Differential-feed adjusting method | By lever (with micro-adjustment) |

| Feed Type | Differential-feed |

| Lubrication | Automatic |

| Machine Type | Overlock |

| Manufacturer’s guarantee | This machine is offered with a 12 month back to base Guarantee |

| Max lift of the presser foot | 7mm (excluding some subclass model) |

| Motor Type | Direct-drive |

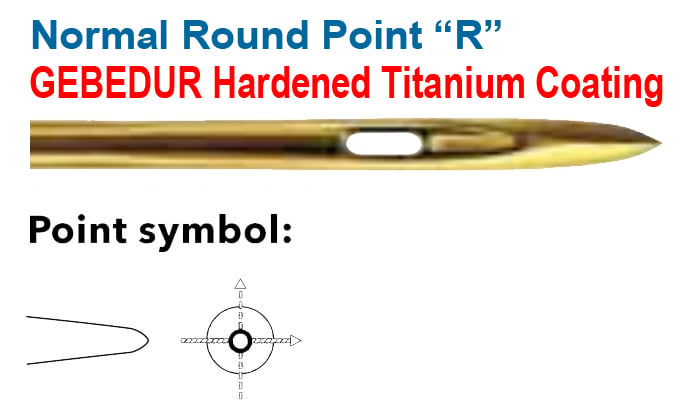

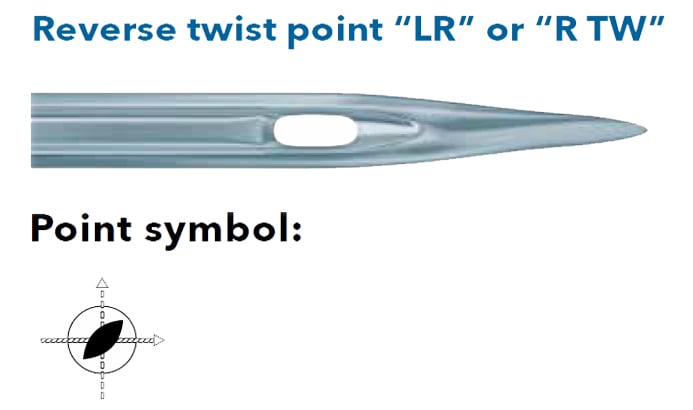

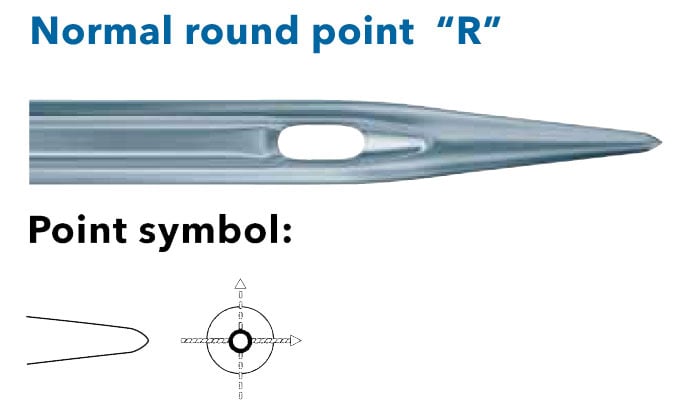

| Needle System | B 27 81x1 DCx21 |

| Needle thread heat remover | Provided as standard |

| Number of threads | 4 |

| Overegging width | 4mm |

| Power requirement | Single-phase 200V~240V 13 amp (can be used at home) |

| Max Sewing Speed (sti/min) | 7,000sti/min |

| Number of needles | 2 |

Name

Review

.jpg)

.jpg)

-min.jpg)

Twin Needle Walking Foot Needle Feed Sewing Machine 6.jpg)

-195x195.jpg)