Jack JK-58750B-005C 1/4 Gauge Split Bar Direct Drive Twin Needle Lockstitch Sewing Machine

Jack JK-58750B-005C 1/4 Gauge Split Bar Direct Drive Twin Needle Lockstitch Sewing Machine

This machine is perfect for upholstery, boat covers, sails, tents, jeans, handbags, and any other heavy materials and leather.

This is a needle feed heavy duty sewing machine suitable for sewing leather and multi-layered fabrics.

This machine comes complete with a head, motor, wheel stand, table, and cotton stand

With a big hook design, the thread amount increases 1.5 times than small hook.

Greatly reduce the frequency of wire change and improve the work efficiency.

Computerized heavy-weight fabrics double-needle lockstitch industrial sewing machine

A series of modern 2-needle lockstitch machines with double transport (feed dog+needle). With standard or enlarged hooks. Closed lubrication system (no typical oil sump) – a small amount of oil is in a closed container. This solution guarantees less oil consumption, better lubrication of machine mechanisms and prevents staining of material during sewing. The standard also includes an LED backlight with the possibility of a 3-step adjustment.

This machine is offered with a 12 month back to base Guarantee

| Features | |

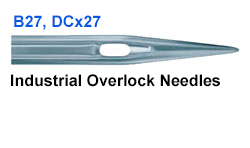

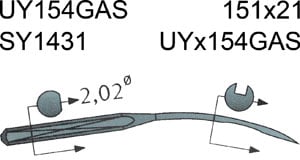

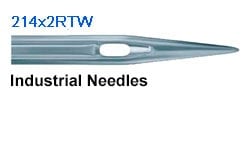

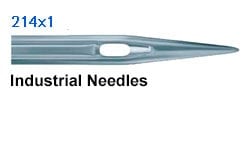

| Accessories | Needles Bobbins Oil Manual |

| Bed Type | Flat-bed |

| Brand | Jack |

| Direct-drive motor | 550W |

| Feed Type | Needle-feed |

| Lift of the presser foot | By hand: 5.5mm By knee: 13mm |

| Machine Level | Standard |

| Machine Type | Lockstitch |

| Manufacturer’s guarantee | 12 month |

| Motor Type | Direct-drive |

| Needle gauge (mm) | 1/4 6.4mm |

| Power requirement | Single-phase 200V~240V 13 amp (can be used at home) |

| Stitch length (mm) | 0 - 5mm |

| Straight Stitch | Yes |

| Table top dimensions | L120cm x W54cm Height Adjustable from 70cm to 86cm |

| Max Sewing Speed (sti/min) | 2,500 sti/min |

| Number of needles | Twin Needle Knock Out Needle Bar |

Name

Review

.jpg)

.jpg)

-min.jpg)

Twin Needle Walking Foot Needle Feed Sewing Machine 6.jpg)

-195x195.jpg)