Juki LK-1900S-HS heavy weight bartack industrial machine

Juki LK-1900S-HS Heavy-weight weight bartack industrial machine

INCLUDES FULLY ASSEMBLED TABLE AND SERVO MOTOR

The sewing machine achieves the best sewing speed of 3 thousand two hundred stitches consistent with min inside the commercial stitching industry.

This Juki computerized industrial stitching machine runs at 3,200sti/min, faster than some other sewing machines ever made.

The demonstrated computer-controlled bartacking system has been dramatically advanced to be an easier-to-use system.

This machine is made for heavy-weight material, such as webbing, leather, and jeans. It is part of the Juki S series and it is the H model.

CONTROL BOX PANEL

Functional settings, such as sample numbers, enlargement/reduction scales, swing speeds, and needle thread tensions can be installed through the operation panel with ease.

The operation panel has been established at an attitude and may be located at the top, bottom, right or left part of the table in line with the operator's preference.

REDUCTION OF NOISE AND VIBRATION

The most important shaft and the thread take-up lever mechanism have been reworked to reduce the sound of noise and feeling of vibration.

As in comparison with the conventional version 1900-BHS, the noise is reduced through 3.9 dB and the vibration is reduced by using 1.65 dB.

EXCELLENT SEAM QUALITY

The Juki computerized business sewing machine comes with a newly developed needle thread grasping mechanism.

The mechanism prevents the thread from slipping off from the needle eyelet at the beginning of sewing, from tangling.

ELIMINATED OIL STAINS

Thanks to our superior dry-head technology, the frame (needle bar and thread take-up) no longer require lubrication.

This prevents the fabric from being stained with lubricating oil.

AUTO-LIFTER

The presser foot lift can be set to a most of 17mm by using the usage of the reverse-rotation needle-up feature in combination with the auto lifter mechanism.

EXCELLENT WORKABILITY AND OPERABILITY

The direct-force head (without a belt), which is built connected to a compact AC servomotor, achieves exquisite responsiveness and improved stop accuracy.

This head helps create a snug working surroundings with reduced vibration and noise.

The armed phase of the system head is outfitted with a hand pulley. This lets in the operator to visually check the needle access points.

Features

51 patterns as standard (with different stitch directions/number of stitches)

Sewing area of 30 mm x 40 mm

Computer controlled, high speed, bar tacking machine

Standard with operation panel with voice guidance system and clock function

Voice guidance system is used to give operator information on how many pieces produced, work progress, operation rate of sewing etc.

Bar-tacking data can be changed easily e.g. enlargement/reduction by entering scale ration into panel

Standard patterns can be allocated to pattern keys

USB Port for updating the machine

Maximum speed 3200 spm

Increased thread trimming speed

Increased speed of work clamp lifting

Large memory capacity to store different scale ratios

Intermittent feed control system

Work clamp lifting height 17mm maximum

LED Lighting (brightness can be adjusted)

Long distance from machine arm to needle for ease of handling material

Semi-dry head (Hook min lubrication)

Stitch length 0.1 - 10 mm

41.2 mm needle bar stroke

Auto lifter

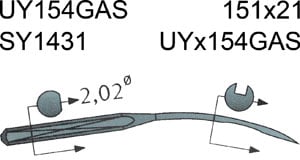

Needle code DB X 5

20,000 stitches can be stored in memory

42 kg machine head

| Features | |

| Application | Heavy-weight materials |

| Auto-lifter | Provided as standard (stepping motor type) |

| Bed Type | Cylinder-bed |

| Brand | Juki |

| Feed Type | Top and Bottom-feed |

| Hook | Standard shuttle hook |

| Lubrication | Semi-dry head (Hook : minute-quantity lubrication) |

| Lubrication oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) |

| Machine Level | Auto-Functions |

| Machine Type | Bartack |

| Motor Type | Direct-drive |

| Needle bar stroke | 41.2mm |

| Needle System | 135x17 DPx17 |

| Needle Thread Tensions | Spring type dial thread tension controller |

| Power requirement | Single-phase 200~240V / 250VA |

| Sewing area | 30mm (L) × 40mm (W) |

| Stitch length (mm) | 0.1~10mm(0.1mm step) |

| Thread trimming | Provided as standard (up / down method) |

| Weight of the machine head | Machine head (include motor) 42kg, Control box 5.1kg |

| Max Sewing Speed (sti/min) | 3,200sti/min✽ (at the time of delivery : 2,700sti/min ✽ ) |

Name

Review

.jpg)

.jpg)

-min.jpg)

Twin Needle Walking Foot Needle Feed Sewing Machine 6.jpg)